Greetings to all my Boise, Eagle, and Meridian Appliance-Repair customers. This is Rich from Western Appliances Repair and I’ll be talking about washer water-level pressure switches and how they operate.

Most modern washers will automatically adjust the water level appropriately based on a feedback voltage which is generated through the use of a pressure switch. The washer water level will be adjusted but also, and very importantly, the washer control board will “know” at what time to run the spin cycle. The control board will not run a spin cycle if it “knows” there is water in the tub.

When a failure occurs in the circuitry you may get an instance where the washer will not spin at all. You may also see the tub overfill or under fill.

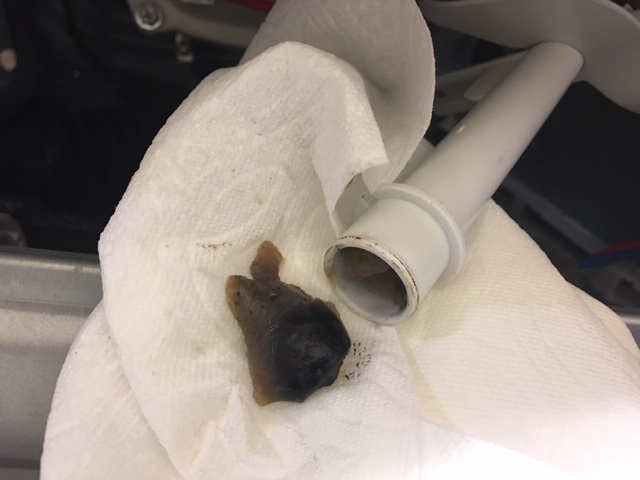

The water level pressure switch relies on air pressure created from an air bell which is located at the bottom of the tub. As the water level increases it puts causes air pressure to increase through the air bell, into an external tube, which is routed to the pressure switch – which is located near the control board. When air pressure is no longer created by the rising water the control board will not function properly. In this instance there is a clog in the air bell that prevented the air pressure from reaching the pressure switch.

This “gook” or build-up, as you can see in the picture, is mostly UN dissolved detergent. When the “cold” wash setting is used extensively, combined with a low quality detergent, the detergent will not dissolve completely and will create problems like this.